Leistungsfähige Präzisionsantriebe für die Handhabungstechnik

Leistungsfähige

Präzisionsantriebe

für die

Handhabungs

-technik

Hebe- und Montagehilfen - die nächste Generation digitaler und intelligenter Steuerung von Seil- und Kettenhubgeräte

Kettenantriebe

Unsere Elektrokettenzüge sind industriell in allen Traglastbereichen bewährt und äußerst robust und zuverlässig.

Seilantriebe

Die e-Motion Balancer sind präzise Hilfen beim Heben, Montieren und beim Balancieren mit Fügemodus.

Bediensysteme

Die große Auswahl ermöglicht stets eine körpergerechte Haltung, auch mit Hilfe einer Funksteuerung

Leichtkransysteme

Zur Montage unserer Antriebs- und Bedien-systeme bieten wir auch passende Kransysteme und Manipulatoren an.

die eine effektive Arbeitserleichterung mit der höchsten Sicherheit verbinden.

Höchste Präzision

neue Maßstäbe mit hochwertigen Kettenzügen

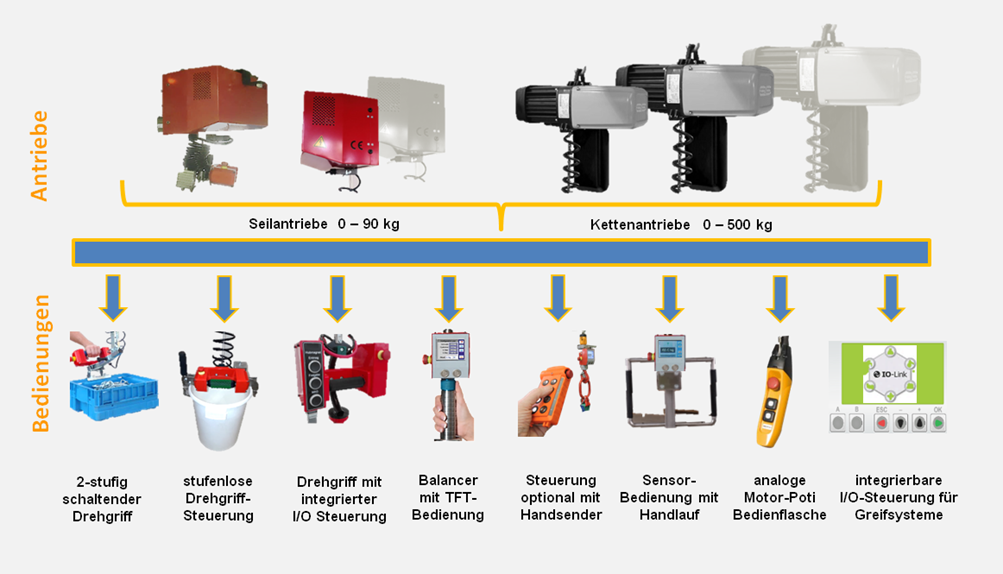

Unser Konzept für mehr Flexibilität

in der Handhabung von Lasten

Seit es digitale Hebe- und Montagehilfen fertigen und vertreiben wir seilbasierte Präzisionsantriebe für die Handhabungstechnik. Insbesondere als Systempartner für die Gorbel® G-Force® Balancer haben wir über viele Jahre die Möglichkeiten digitaler und intelligenter Balancer unter Beweis gestellt. Im Rahmen unserer Dienstleistungen bieten wir auch weiterhin Service- und Reparaturleistungen für die G-Force® Balancer an.

Aufgrund unserer Erfahrungen hinsichtlich der stetig neuen Anforderungen in den Handhabungsprozessen der Fertigung und Montagetechnik sehen wir auch, dass der Bedarf an extrem langsamen und präzisen Antrieben wächst. Immer wichtiger werden aber auch die Anforderungen an die Sicherheitskonzepte der Antriebssysteme und deren Steuerung.

Daher bieten wir nicht nur ein exakt abgestimmtes Antriebssystem, sondern auch mehr Flexibilität zur Auswahl optimaler und ergonomischer Bediensysteme.

Wir planen mit Ihnen die passgenaue Handhabungshilfe, und ermitteln die optimale Systemkonfiguration für eine effektive Arbeitserleichterung. Dabei erfassen wir Ihre Aufgabenstellung am Arbeitsplatz.

Gerne informieren wir Sie persönlich über die Vorteile der digitalen, intelligenten Antriebstechnik im Einsatz gegen die Schwerkraft, rufen Sie uns an: +49(0)2335 8499-153

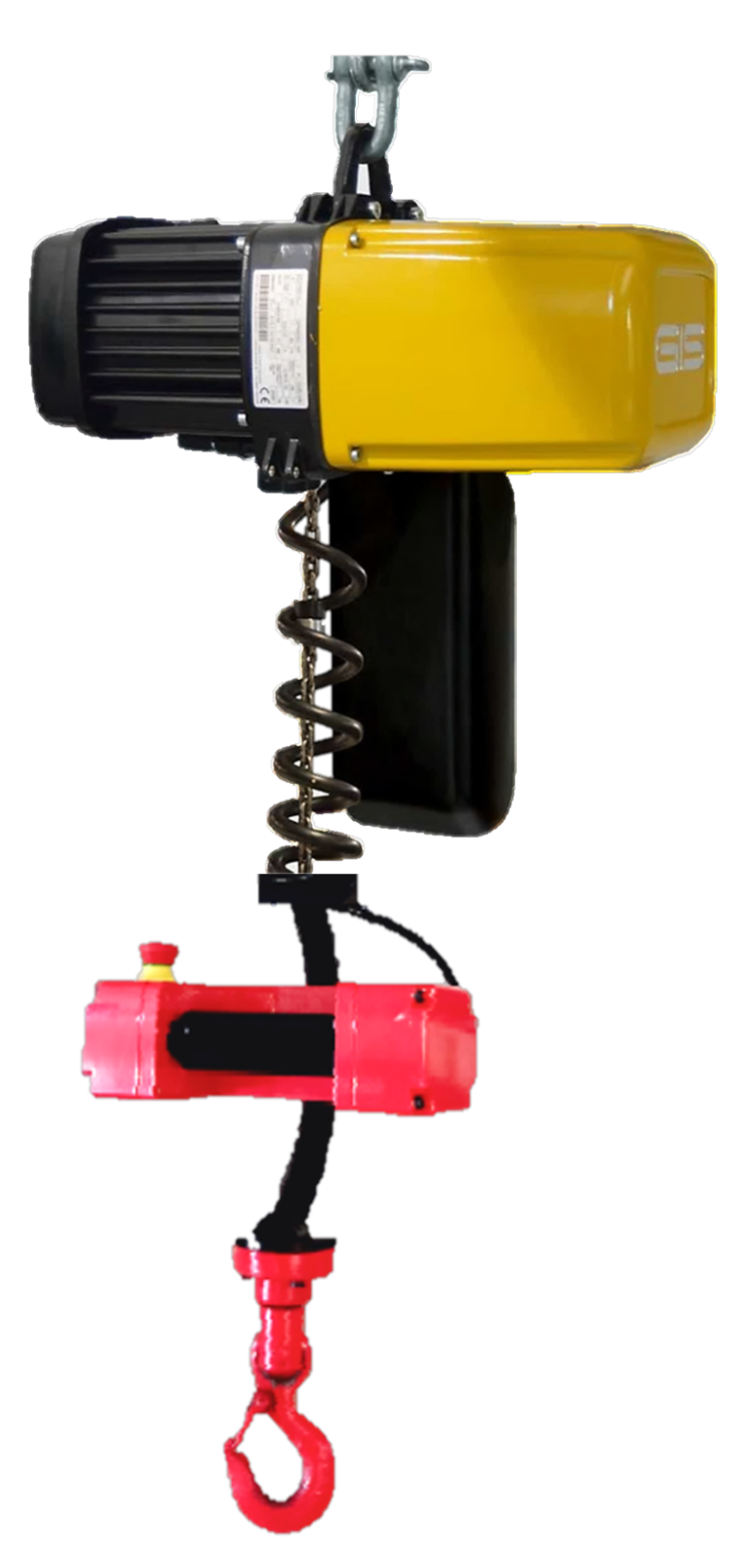

Unsere Elektrokettenzüge

Die neue Generation industrieller Last-Manipulator-Systeme

Auf Grund der Marksituation und neuer Fertigungstechnologien stellen die Aspekte der Zuverlässigkeit, Sicherheit, Robustheit, aber auch Recyclingfähigkeit und Ergonomie wachsende Anforderungen an die Antriebstechnik, speziell in der Handhabungstechnik.

Bei der Entwicklung der neuen Generation kettenbasierter Last-Manipulator-Systeme war eine zentrale Zielsetzung die Vorteile bestehender Systeme zu nutzen, um den Wartungsaufwand und damit die Betriebskosten zu optimieren.

Warum Kettenzüge in der Handhabungstechnik verwenden?

Im Gegensatz zu den oft verwendeten, seilgebundenen Systemen verhindert die neue Generation kettenbasierte Hebehilfen das Drehen der der Last bei der Aufnahme. Zwar haben Seilbalancer einen ruhigeren Lauf, aber auch einen horizontalen Versatz über den Hubweg, der bei präzisen Montagevorgängen hinderlich ist. Kettenzüge haben diesen horizontalen Versatz nicht, eignen sich daher optimal für präzise Hebe- und Balancieranwendungen.

Die Komponenten des Last-Manipulator-Systems

Für unsere Kettenzüge nutzen wir weltweit eingesetzte Antriebe aus der Schweizer Fertigung. Diese robusten, modularen Systeme von überragender Fertigungsqualität und abgesicherter Rutschkupplung, erfüllen wir alle erdenklichen Anforderungen. Speziell der ruhige Lauf des Kettentriebs und die hohe Schutzklasse bieten eröffnen neue Anwendungen und höchste Verfügbarkeit in den Traglastbereichen bis 125kg / 250 kg und 500 kg.

Weitere Eigenschaften ergeben sich aus der neuesten Elektronik und Software mit denen wir auch das Innovationstempo der IOT-Technologie berücksichtigt haben.

Haben wir Ihr Interesse geweckt? Dann rufen Sie uns an: +49(0)2335 8499-153

Unsere Seilantriebe

Beispielhaft für die intuitive Bedienung von Hebehilfen ist noch immer die Funktionalität unsere patentierte Drehgriffsteuerung, die eine exakte Lastführung mit feinfühliger Antriebssteuerung verbindet. Der e-Motion Seilantrieb wird daher bevorzugt für schnelle Arbeitszyklen mit bis zu 30m/min. eingesetzt.

Die Lastaufnahmemittel sind so verschieden wie die benötigten Bediensysteme und reichen vom einfachen Lasthaken über Schnelltrennkupplungen bis hin zu komplexen kundenspezifischen Lösungen. Unser Kupplungssystem ist kompatibel und daher leicht in OEM Anwendungen zu integrieren.

Wir unterstützen Sie bei der Systemauswahl, rufen Sie uns an: +49(0)2335 8499-153

Unsere Bediensysteme

Drucktasten

Das Bediensystem mit Drucktasten wird mit Hilfe eines Standardsteuerschalters realisiert.

Drehgriff

Das Bediensystem mit Drehgriff stellt eine Besonderheit unter den weltweit verfügbaren Bediensystemen dar.

Balanciergriff

Das Bediensystem

mit einem Balanciergriff ist in verschiedenen Varianten verfügbar.

Die Bediensysteme bilden die Schnittstelle zwischen den Hebe- und Montagehilfen und dem Bediener. Daher sind eine intuitive Bedienweise und die Ergonomie von besonderer Bedeutung für die Leistungsfähigkeit des Gesamtsystems. Die Auswahl an Bediensystemen gewährleistet eine körpergerechte Haltung für jede erforderliche Arbeitshöhe für eine präzise Regelung der Antriebssysteme.

Drucktasten (digital)

Mit einer handelsüblichen, zweistufig tastenden Bedienflasche ermöglichen wir mit unserer neuen Steuerung einen sanften Anlauf. Mit Betätigung der zweiten Tasterstufe erfolgt eine durchgängige Antriebsbeschleunigung. Auch beim schnellen Umtasten wird der Drehrichtungswechsel ohne Zwischenstopp und dynamisch ausgeführt. Diese Drucktaster-Bedienung bieten wir anwendungsspezifisch zum Ein- und Anbau an Lastaufnahmemittel an.

Drehgriff (digital oder analog)

Das bewährte Bediensystem mit Drehgriff stellt eine Besonderheit unter den weltweit verfügbaren Bediensystemen dar. Die intuitive Bedienung verbindet exzellente Eigenschaften bei der Lastführung und exakter Positionierung durch die stufenlose Antriebssteuerung; die perfekte Einhandbedienung. Dabei ist es unerheblich, ob Anwender Links- oder Rechtshänder sind. Dieses Bediensystem ist digital oder analog für alle unsere Antriebe verfügbar und kann auch überall eingesetzt werden, wo 2-stufige Taster im Einsatz sind.

Balanciergriff (analog)

Bei der Balancer Bedieneinheit erfolgt die Hub-und Senkbewegung proportional zur Handkraft am Stabgriff, durch minimale Kraft ist ein ermüdungsfreies Arbeiten gewährleistet. Auf einfache Weise können alle Parameter, z.B. Sensitivität, Beschleu-nigung am TFT-Display eingestellt werden. Unterschiedlichste Lasten werden nach dem Freiheben sofort erkannt und aktivieren automatisch den Balancer-Modus. Der zusätzliche Füge-Modus erleichtert die Montage komplexer Teile und beim Auf-setzen der Last kann den Balancer-Modus automatisch beendet werden.